Maintenance

Solutions that unlock the true potential of your business

MAINTENANCE

Marine PRO-V guarantees the correct planning, traceability and control of maintenance through an integrated management system; both in the facilities and in the planning and service orders made.

Why is it important to have a maintenance plan?

It is a priority to have a maintenance plan in the industrial gases industry due to several reasons:

- Safety: Preventive equipment maintenance helps identify and correct potential equipment problems to prevent dangerous accidents from occurring. This protects our employees and customers.

- Reliability: Properly maintained equipment is less likely to fail ensuring higher availability and less downtime.

- Efficiency: Maintains its optimal performance and reduces operating costs.

- Longevity: Helps extend the life of the equipment, reducing the total cost in the long run.

- Regulatory Compliance: Many regulations and standards require regular maintenance of equipment to ensure that safety requirements are met.

What kind of maintenance do we offer at Marine PRO-V?

We offer the maintenance of cylinders with which industrial gas is handled, since with good care a cylinder can have a useful life of 60 years, allowing your investment in equipment to last much longer.

According to the needs, 2 different types of maintenance can be carried out, preventive and corrective.

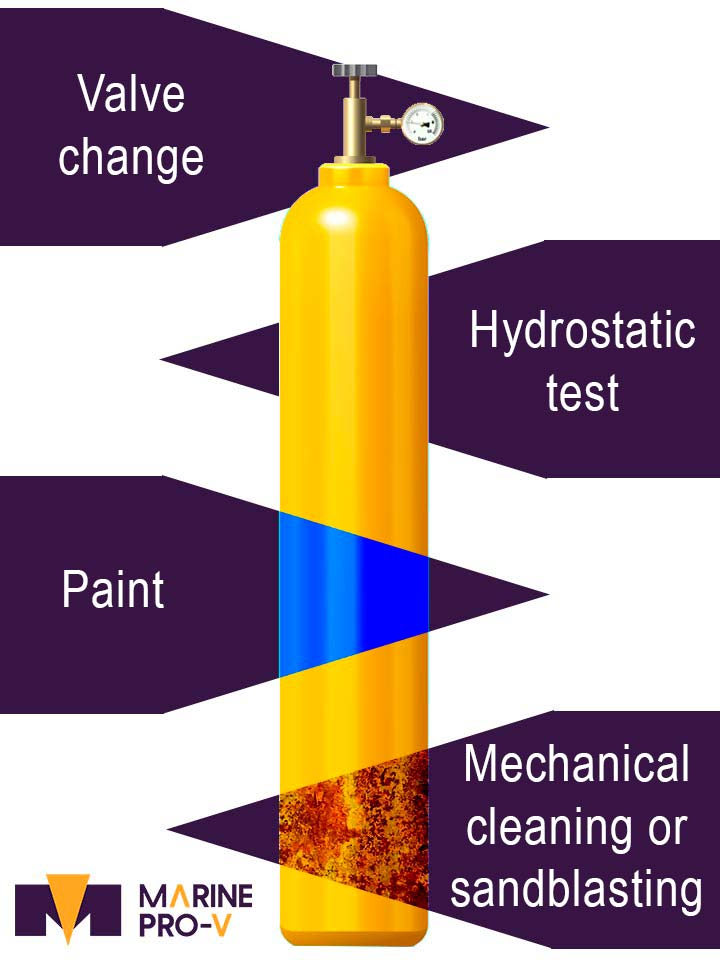

- Corrective maintenance we offer valve change.

- Preventive maintenance, we review the integrity of the equipment and determine the type of intervention it needs.

- Hydrostatic test: it is a pressure test that is carried out to verify the integrity and safety of the cylinder. This test must be performed every 5 years.

- Mechanical cleaning: removes dirt, rust and other contaminants from the cylinder surface. This technique is less abrasive and is primarily used to clean the exterior of cylinders.

- Sandblasting: is a cleaning process that uses high-pressure abrasive jets to clean the surface of the cylinder. It is mainly used to remove oxide layers and other contaminants that are difficult to remove with mechanical cleaning.

- Paint: the paint used in industrial gas cylinders is specially designed to withstand extreme conditions of temperature, pressure and exposure to chemical products. It is resistant to corrosion and weathering.